Are you an OEM Supplier? Want to penetrate into the Aerospace, Defense, Firearms, or other Commercial markets?

Aerospace and Defense markets are exceedingly difficult for Suppliers to gain business development traction. These markets come with high barrier entry requirements such as AS9100/ISO9001 quality certifications, significant Cybersecurity CMMC & CUI requisites, ITAR requirements, etc. Visioneers can assist you in understanding and navigating the barriers to market entry. Visioneers can provide representation of your companies products and services to develop business within these sought after OEM’s and Prime Contractors. We at Visioneers have curated thousands of OEM decision-maker contact relationships. Partnering with Visioneers ensures that your company will benefit from our 15+ years serving the Aerospace, Space, and Defense markets. By working with Visioneers, we’ll evaluate your business and provide a complete strategic roadmap to build long-term business relationships that provide year-over-year revenue generation for your company’s growth.

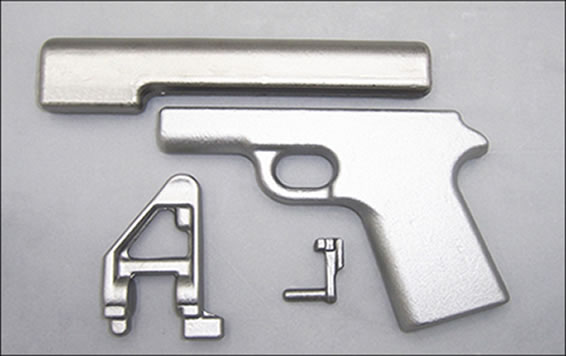

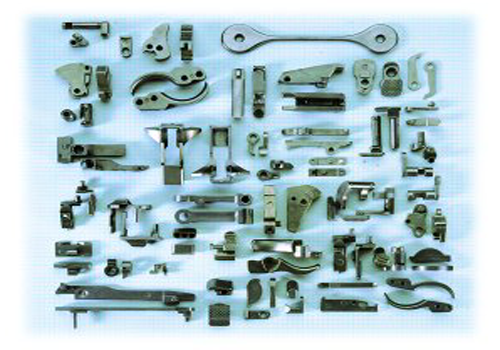

Firearms Supplier Sales Representation